meltblown nonwoven fabric

Product

1.Material:100% Polypropylene

Width:10cm-160cm

Color:White and Black

Weight:9-300gsm

Pattern:Embossed

Place of origin:China

Grade:BEF95/99, N95/99, FFP1/2/3

Package:one roll into polybags and nylon bags

2.Feature:

1. High strength, small difference at longitudinal and longitudinal direction .

2. Acid, non-toxic, non-radiation, harmless to human physiology;

3. With excellent breathability;

4. Master batch dying, never fade

5. Smooth, bright color, roll slitting, easy use, best quality .

3.Application:

1) Filter material Gas filter: medical masks, room air conditioners filter material Liquid filter: beverage filtration, water filtration

Instead of woven fabric and spun-bonded nonwovens.

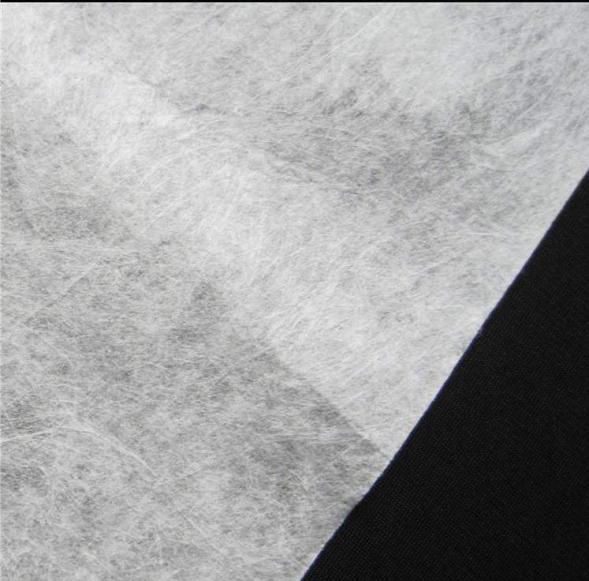

2)Medical & Health Material Surgical Mask: inner and outer layers with spunbond material, in the middle is melt blown fabric.

Meltblown fabric characteristics of high strength,good hand feeling,effective bacterial barrier penetration,through blood but can breathe; to prevent cross infection,reduce dust and hairiness of shedding,provide the best operation environment; reduce fox personnel labor,convenient storage,supply and replacemant;wear and easy to ues,low price.A large number of applications inthe following medical industry.

3) Environmental protection material (oil absorbent material)

Meltblown fabrics mainly adopt PP raw material,because PP is admost not water absorbent but has a very good oil absorption and meltblown fabric with high porosity and high specific surface area,so the meltblown fabric has good oil absorption properties.After the experiment,it can absorb more than its own weight of 17-20 times of oil.According to these characteristics can be made into oil absorption felt,filter,and other applications in the oil-water separation,environmental protection,environmental protection of ports and shipping and handling of accidents in.

4) Clothing Materials meltblown nonwovens by the microfiber into a net, so its very soft feel. And the fabric of small aperture, high porosity, with very good wind resistance and good air permeability, light weight, is currently doing the best material for clothing insulation materials.

5)Sound-absorbing material: more interconnected pores,more subtle fiber matrix,bring light,fluffy appearance structure.In order to make it can than existing sound-absorbing properties of glass fiber,cotton,wool spinning waste materials such as better.

6)Air filtration: Bag type air filter by PP/Pet binary points conform to the material,with a three-dimensional network structure,PET material in the supporting frame to,providing the filter layer of the pause,so that material in order to ensure the efficiency of colleagues has a lower resistance.The high efficiency particulate air filter material using advanced long-term electrostatic electret technology,the electrostatic long -term preservation in the fiber struct-ure and realize the high/low resistance/high dust holding.

The material to monolayer membrane,tubular membrane,band filter and other forms of supply. The bags type filter can be directly assembled into the filter box.

4.Packing and shipping