Shoe material stitch bonded fabric Green innovation drive industry upgrade, into the footwear manufacturing core can assign materials with the global footwear market's rising demand for functional, environmental protection materials, shoes material stitch bonded fabric as an important category in the field of nonwovens, is relying on unique technology and multiple advantages, from the traditional shoes material supporting growth as main industry innovation. The current industry is showing a development trend of "scale expansion, environmental protection dominance, and technological iteration". In the future, it will accelerate breakthroughs in the green, functional, and high-end tracks, injecting new impetus into the footwear manufacturing industry.

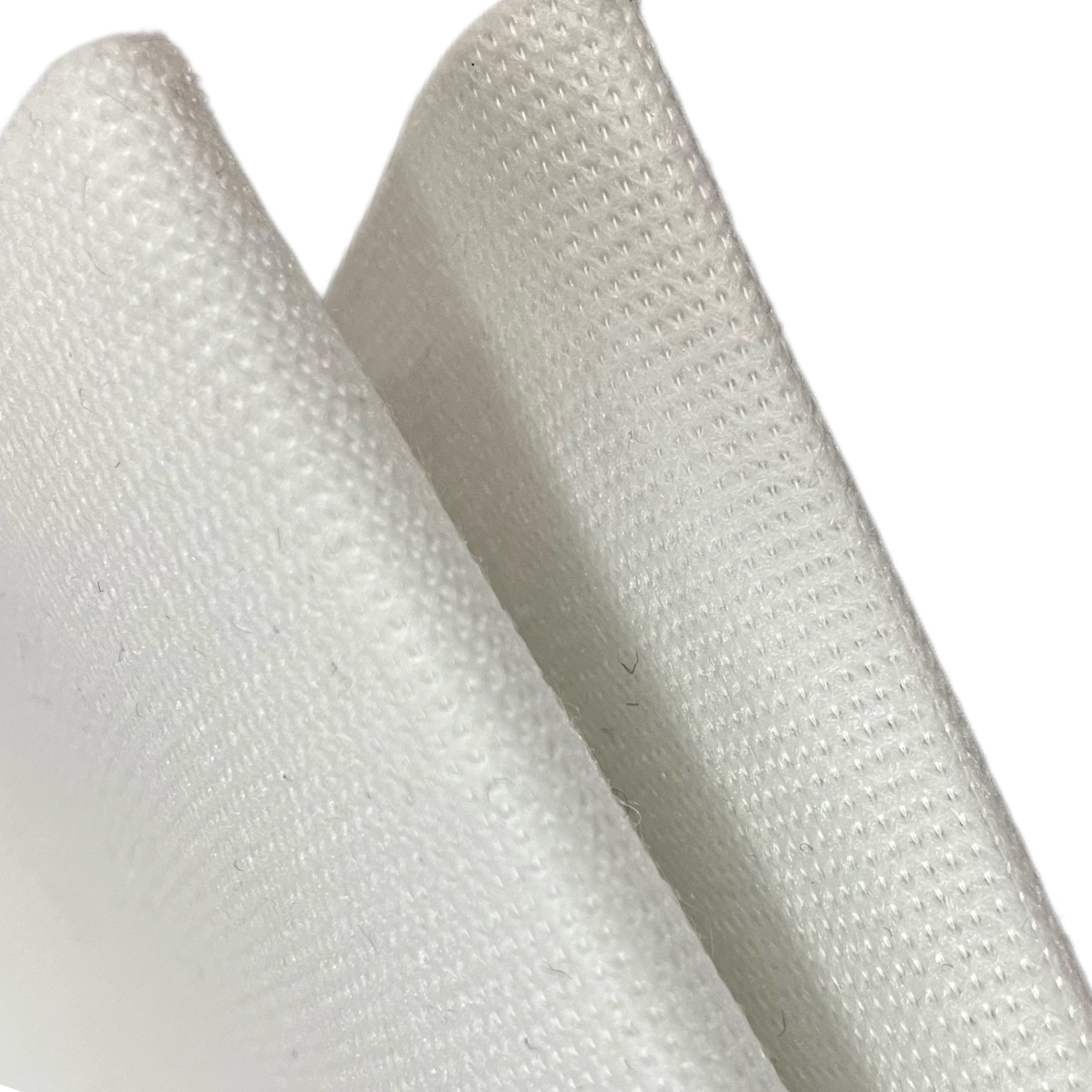

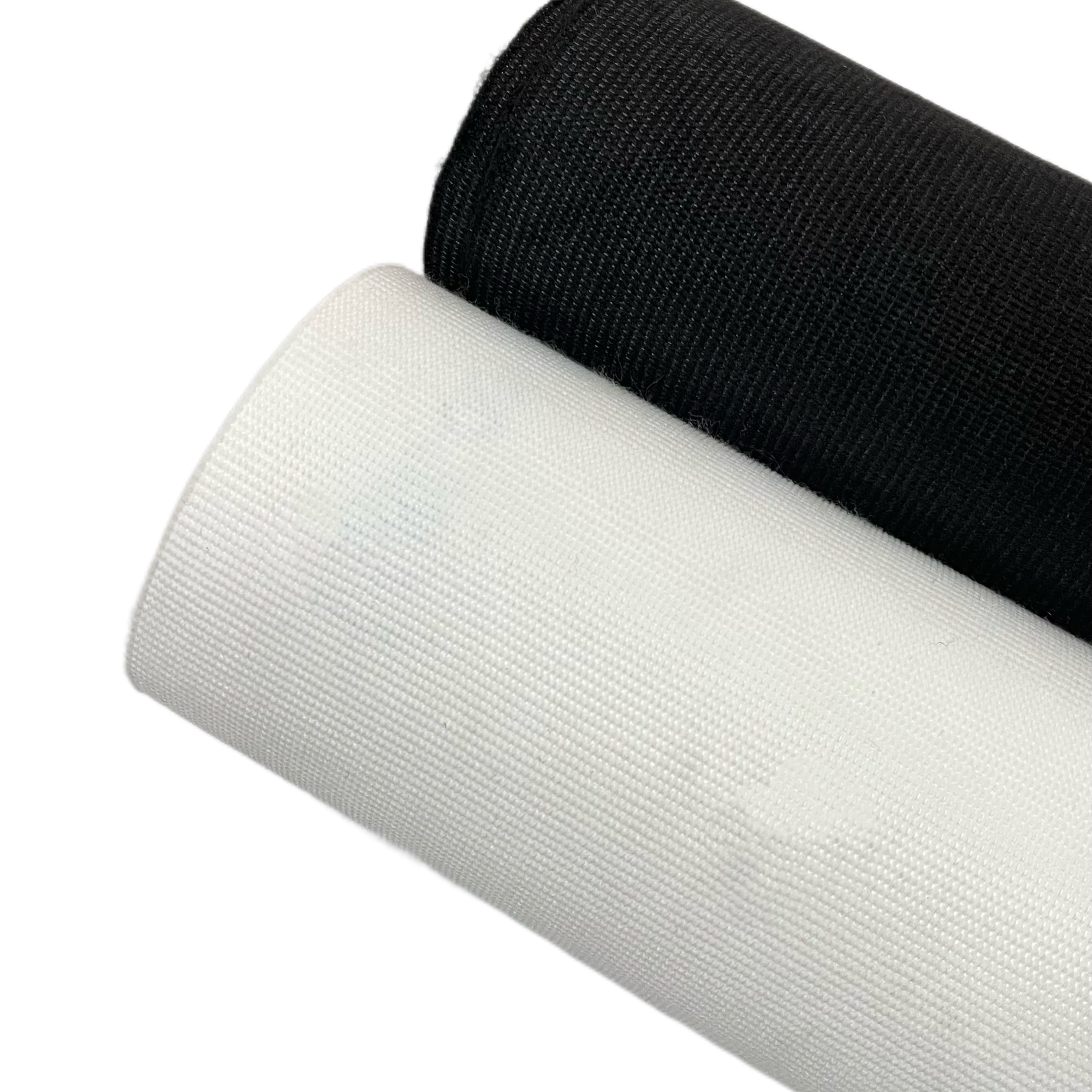

Stitch Bonded Fabric is a nonwoven fabric in which the core is reinforced into fabric through needling or sewing processes. It is a key material specifically used for shoe manufacturing. It is not a traditional textile cloth without spinning weaving steps, but directly with fibre processing molding, has been widely applied in the field of shoes materials.

Domestic and international development trends

Domestic Market

Import and Export Situation: The export volume of self-adhesive stitch bonded fabric in China has been increasing year by year. In 2023, the total export value reached 410 million US dollars, mainly sold to Southeast Asia, the Middle East, and South America. It is expected that the export scale will approach 580 million US dollars by 2025. Imports mainly consist of high-precision coating equipment and special functional adhesives, with a relatively high degree of dependence on foreign sources.

International Market

Market Size Expansion: It is predicted that by 2025, the global market size of sewn stitch bonded fabric will reach 150 billion US dollars, with a compound annual growth rate of over 5%. In 2019, the global market size of environmentally friendly sewn stitch bonded fabric products reached 10 billion US dollars and is expected to maintain a high growth rate in the coming years.

Regional Growth Disparities: The Asia-Pacific region, especially China and India, has huge growth potential. With rapid economic and technological development, the demand for stitch bonded fabric, an advanced product, is rising rapidly. North America shows a growth potential of 10% to 15% due to the stable demand in the high-end clothing market and increased investment in technology. The European market is expected to develop steadily from 2025 to 2030. Driven by technological innovation and design trends, the demand for high-end and fashionable applications of Stitch Bonded fabric is expected to increase steadily. Although the market size in South America and Africa is relatively small, the growth rate is fast.

Environmental Demand Promotion: Global attention to sustainable development has driven the demand for Stitch Bonded fabric. The increased consumer focus on environmentally friendly products and government support for green industries have made Stitch Bonded fabric, which focuses on the production of renewable materials, a new growth point. For example, the compound annual growth rate of the global organic textile market is expected to reach 15% by 2030.

The balance between cost and performance

I.Core Advantages: Key Characteristics Adapted to the Shoe-Making Industry

1. High cost-effectiveness: The raw materials are mainly polyester, nylon, and other chemical fibers, with lower production costs than traditional cotton fabric and genuine leather. The production efficiency is high, meeting the mass production needs of shoes.

2. Strong formability: By adjusting the weaving method and thickness, it can be made into various forms from thin interlining to thick support materials, adapting to the needs of different parts of shoes.

3. Lightweight: Compared to rubber and leather, Stitch Bonded fabric of the same thickness is lighter, helping shoes achieve "lightweight" design and improving wearing comfort.

4. Easy processing: It does not fray easily during cutting and has good compatibility with adhesives and sewing threads, fitting well with the splicing and bonding processes in shoe-making, reducing production waste.

II. Key Performance: Meeting the Functional Requirements of Shoe Applications

1. Mechanical Strength: It has excellent tensile and tear resistance. When used as a shoe upper reinforcement or insole layer, it can withstand the friction and pressure of daily walking, thereby extending the shoe's lifespan.

2. Breathability: The multi-pore structure formed by the sewing and knitting process allows air circulation, reducing foot sweatiness and is particularly suitable for shoes that are worn for long periods, such as sports shoes and casual shoes.

3. Weather Resistance: It has strong resistance to temperature changes and slight dampness, and is less likely to deform or mold due to environmental influences, meeting the usage requirements in different climate regions.

4. Dimensional Stability: After washing or prolonged use, it has a low shrinkage rate, maintaining the original shape of the shoe and avoiding discomfort caused by material deformation.

III. Main Applications: Covering Multiple Parts of Shoes

1. Upper-related:

Serves as a "reinforcement layer" for the upper, used in areas prone to wear such as the toe and heel to enhance structural support.

- Used as a lightweight upper base material, combined with mesh and knitted fabrics to improve the breathability and strength of the upper.

2. Shoe Accessories:

Acts as a "supporting interlining" for the tongue and insole, enhancing the stiffness of the accessories while maintaining breathability.

Used as a binding material around the shoe opening and eyelet areas to reduce fabric friction against the skin.

3. Sole and Lining:

Functions as an "intermediate layer" for the sole, connecting the sole and upper to improve the sole's cushioning and stability.

Used as a "moisture-absorbing interlining" for the inner lining to absorb sweat from the feet and keep the shoe interior dry.

The future market prospects for shoe materials made from Stitch Bonded fabric are extremely optimistic. Driven by multiple factors such as policy support, technological upgrading, and market demand, the industry is experiencing both scale expansion and quality improvement, with a highly predictable growth trajectory.

Policy and demand resonate, and environmental attributes become the core competitiveness.

Strong policy support has paved the way for industry development.

The "Textile Industry Quality Improvement Action Plan (2023-2025)" of China clearly supports the development of new bio-based fibers and green manufacturing technologies. The Ministry of Industry and Information Technology, in collaboration with the Ministry of Finance, has invested 430 million yuan in special funds for technological research and development and industrialization application of Stitch Bonded fabric and its upstream raw materials.

The green preference of the demand side has continued to strengthen. 67% of consumers are willing to pay a premium of 5% or more for shoe products containing environmentally friendly materials. International brands such as Nike and Adidas have significantly increased the proportion of environmentally friendly materials in their supply chains. The environmental characteristics of Stitch Bonded fabric shoe materials, which are based on recycled PET fibers, precisely align with this trend. The application proportion of recycled polyester fibers in Stitch Bonded fabric shoe materials reached 38% in 2024, and it will continue to increase in the future.

Conclusion:Currently, Stitch Bonded Cloth is in a critical period of "deepening environmental protection transformation, achieving technological breakthroughs, and upgrading market demand". Its comprehensive advantages in function, cost, and environmental protection have made it an important choice for shoe manufacturing enterprises to reduce costs, increase efficiency, and enhance product competitiveness.

For industry enterprises,needs to seize the trends of greenification, intelligence,and continuously improve product value-added and brand influence through raw material upgrading, technological research and development, and market expansion. In the future, stitch bonded fabric will not only become the core basic material for shoe manufacturing, but also play a key role in promoting the sustainable development of the shoe industry and meeting consumers' high-quality demands. The industry market size is expected to exceed 20 billion yuan in 2026, initiating a new growth cycle.

Post time: Oct-30-2025